This is an excerpt from “The Intelligent Hand” by David Binnington Savage.

The most important thing the bench does for you is hold a job whilst you work on it. (I remember my early days without a bench, struggling to hold work with one hand whilst cutting with the other. I am amazed I came out without more damage to my digits. The opportunity to saw off part or all of my hand was a daily event.) The bench is just a giant, flat holding device that allows you to get into the correct position to do the work properly. You are then free to concentrate on balance and being in control. That’s what matters – control.

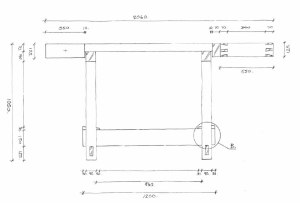

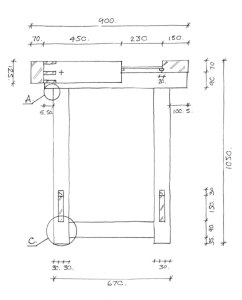

There are a few things a cabinetmaker’s bench has to be. It has to be heavy. You will be exerting horizontal and vertical forces on it, and you don’t want it moving around – so spend some money on timber and make it heavy.

Make your bench to suit your height. This is critical. Many benches I see are very low. The bench height we suggest has rewarded us with strong, undamaged backs. It’s a high bench surface set up for general planing. To determine the right height for you, stand alongside a bench. Bend your elbow. Extend the forefinger and thumb of your left hand. Touch your thumb to your elbow. The point of the forefinger is where your benchtop should be. This will do for almost all work. In case you do need to get on top of a job, keep a small “hop-up box” stored beneath the front rail.

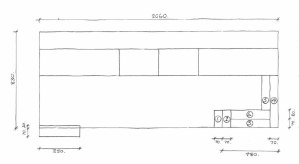

The bench has to have tool well. This is the place to gather the tools in use for a given project. The working surface of the bench should be kept as clear as possible at all times. The benchtop is for the job at hand – nothing else. We know that this game is about skill with speed, and speed is about organisation and picking up and putting down tools fast. Thinking ahead, not being slowed down by a lost chisel in a pile of shavings, is key. We go nuts about such professional practice at Rowden. At the end of day, we put tools away sharp. I know you are tired, but sharpen your tools, sweep the benchtop, sweep the floor – then go home.

Benchtops need to be swept down regularly to keep them free of dust and shavings. Christopher Schwarz sent me this brush as a memento of our visit to Shaker Village at Pleasant Hill. Just look at the design and workmanship! The ends of the bristles thin down to fine strands, and at the bottom they form not a straight line but a gentle arc. Perfect for this job. Look at the binding wrapping elegantly in groups of three, then a gap, gathering more with the movement of each group of three down the handle. At the base, the full handle is bound with an inexplicable hanging hook, coming from the centre of the binding. How did they do that? This, Chris calls a Turkey Wing, I call it the best bench brush ever to have been made.

You can go a long way with great bench, a bag of good, sharp hand tools and good bench light. As my eyes have dimmed, the number of bench lights I need has increased – but you will likely need only one, a good one that can be moved around all over the place.

The tool well collects everything from shavings to dust, tea mugs to half-eaten sandwiches. That’s what it’s for. The bench surface is golden territory – keep it clear and clean; do it no damage. When making this surface, you will respond to the timber that you actually have available. But don’t be tempted to make the bench surface too wide. You need to keep this surface flat, and if it’s very wide, you will need very long arms to flatten it…and the task will be tiresome and not done as regularly as it should. There will come times, usually when developing third-scale prototypes, that you use this bench surface as a datum reference surface – so it’s important to keep it spot on. Our practice is that at the end of every big job, the surface is dressed lightly with a bench plane. Just a shaving all over gets it clean, flat and new – ready for the next job.

— Meghan B.