Excerpted from Peter Galbert’s “Chairmaker’s Notebook.”

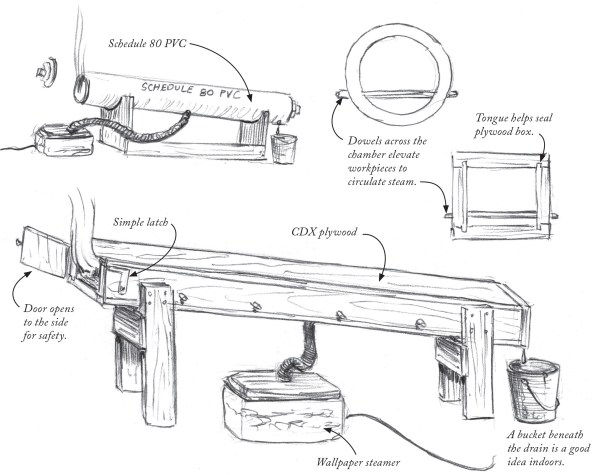

There are many options for the box that traps the steam and holds the parts to be bent. Schedule 80 PVC pipe works fine, but I think it’s expensive overkill. I’ve seen schedule 40 pipe melt when hooked up to a powerful steamer.

I prefer a CDX plywood box that is barely large enough for the bend at hand. I’ve found that a box with an interior of 4″ x 3″ x 62″ is large enough for almost all of my needs. Don’t bother to paint or seal the wood; you’ll simply be trapping the moisture and inviting mold growth. To function, the box shouldn’t be NASA airtight; as a matter of fact, you should see steam leaking out, which lets fresh hot steam circulate to all regions of the box. If the steam can’t circulate, then you are relying on conduction, which doesn’t transfer heat as well as convection. I keep a thermometer in the top of my box and with this sort of box, the temperature climbs to 210°F. Standard woodworking glues won’t hold up to the heat and moisture so I rely on polyurethane glue, tongue-and-groove construction and screws to hold my box together.

To allow the cooled condensed vapor to drain, the whole box should be at an angle and have a drain hole at its lower end. I usually put the port for the steam hose in the center of the box near the most extreme part of the bend. To prevent steam burns, the door of the steamer should hinge on the side so that your hand is never above the open door. Steam burns come on fast and can do plenty of damage. I usually put the end of the steamer with the drain port on a lid from a plastic tub to collect the liquid that drains out.